Mitigating Risks of Large Hydrogen Inventories: The Adaptive Split Platform Approach

In response to the growing demand for hydrogen as a clean power source, the emergence of gigawatt-scale green hydrogen production installations near offshore wind farms is on the horizon. While various pilot projects and small-scale facilities are underway in the Dutch North Sea, large-scale offshore green hydrogen installations are yet to be operational. However, several projects, including the recently announced 100-MW Demo1 and 500-MW Demo2 in Europe, are in development and expected to operate post-2031.

To address the challenge of scaling up production while minimizing environmental impact, McDermott is exploring the potential for large offshore green hydrogen production installations. Leveraging their expertise in offshore high-voltage direct-current (HVDC) transmission and onshore electrolysers, McDermott is considering a platform structure designed to accommodate electrolyser facilities with a capacity of 300 to 500 MW.

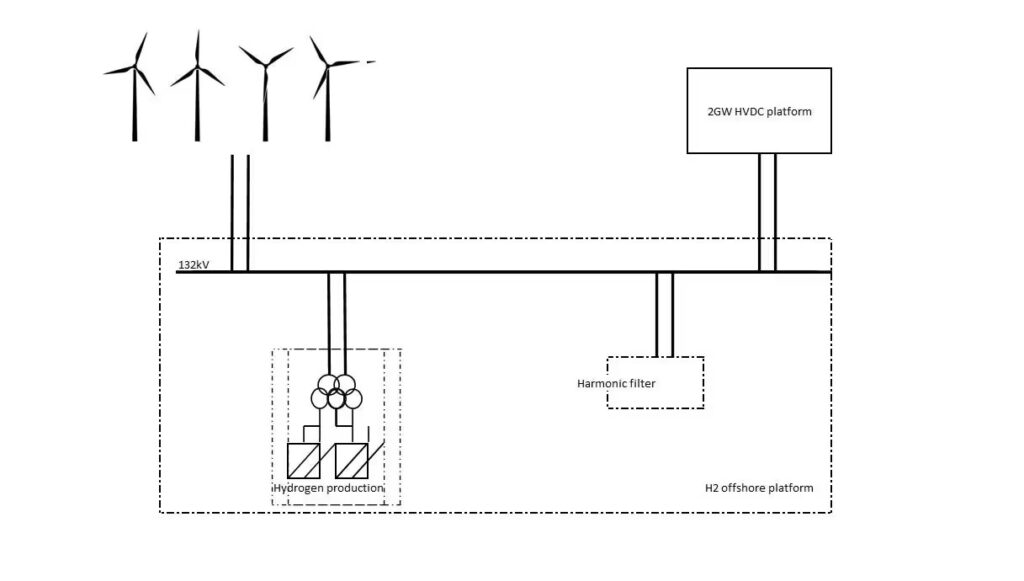

After evaluating different concepts, the study team has focused on a centralized configuration with a 500 MW electrolyser capacity, including the use of a 10-MW PEM electrolyser. This facility could connect to an offshore wind farm and serve as an intermittent facility between the wind farm and a 2-GW HVDC installation, providing flexibility in choosing the most profitable operating mode.

Safety has been a paramount consideration in the design, with a fully independent hydrogen facility featuring split platforms for reduced risk. The utility platform, housing supporting services and power transformation, is linked to the process platform through a bridge to ensure personnel safety. The design also incorporates separation principles to minimize potential hazardous releases and electrical installations away from high volumes of hydrogen and oxygen.

The offshore platform’s electrical system is based on a 132-kV distribution voltage, potentially becoming the next standard offshore. The facility’s ICT system is designed for unmanned/remote control, assuming a connection through a redundant fiber optic network and a control room onshore.

The production platform, with 24 arrays on each deck level, supports a compression system, ventilation, and air handling systems. The utility topside accommodates electrical and utility systems, living quarters, and maintenance rooms. McDermott has designed identical jackets for both platforms, with the flexibility to scale up or down based on project needs.

In conclusion, the concept of offshore hydrogen production presents a technically feasible alternative to meet global targets for increased use of renewable energy. McDermott’s expertise in offshore knowledge and hydrogen production positions them to support the development of this innovative approach, contributing to the transition towards a more sustainable energy future.